This document will need photos for each step.

While this article will focus primarily on the Motronic 3.3.1 system in the E36, the general information will apply to many other similar systems. The engine computer is often referred to as the ECU or the DME.

The ECU is located in a cubbyhole behind the right side shock tower in the engine bay. In stock form there are both an acoustic cover and a weather tight cover that seal the compartment.

The acoustic cover is held on with 3 push clips in its midline, and a few 10mm large plastic nuts at the base.

Only the push clips are required to be removed. Using a small screwdriver, pry back the center pin and the rest of the fastener will easily be removed. Do this for all three clips.

With the acoustic cover removed, the 4 Phillips head screws will be visible. Unscrew these but do not pull them out of the cover.

With the screws undone, you will be able to pull the top of the cover towards the front of the car, and then pull up. The bottom of that cover/door fits into a slot on the chassis.

With the door removed, the DME is now exposed. To remove it, simply slide it forward. It is held in with spring locks, so there will be some friction/resistance.

With the DME out of the compartment, remove the plug. To unlock the plug from the DME, pull the silver latch on the top of the plug away from the DME.

With the DME out of the car, set it on your clean dry workbench.

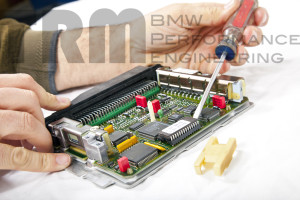

Remove the cover. (bend lock tabs. remove torx screws if so equipped.)

Remove the chip cover/lock.

Remove the chip. (If this ECU already has a chip, make sure you remove all of whatever was there, including any aftermarket daughter boards.)

See photo for “Daughter Board / Encryption Board” – Note extra circuit board above chip socket.

Many customers will not have access to a “Chip Puller”. If you are using a prying device work the chip up from each end slowly.

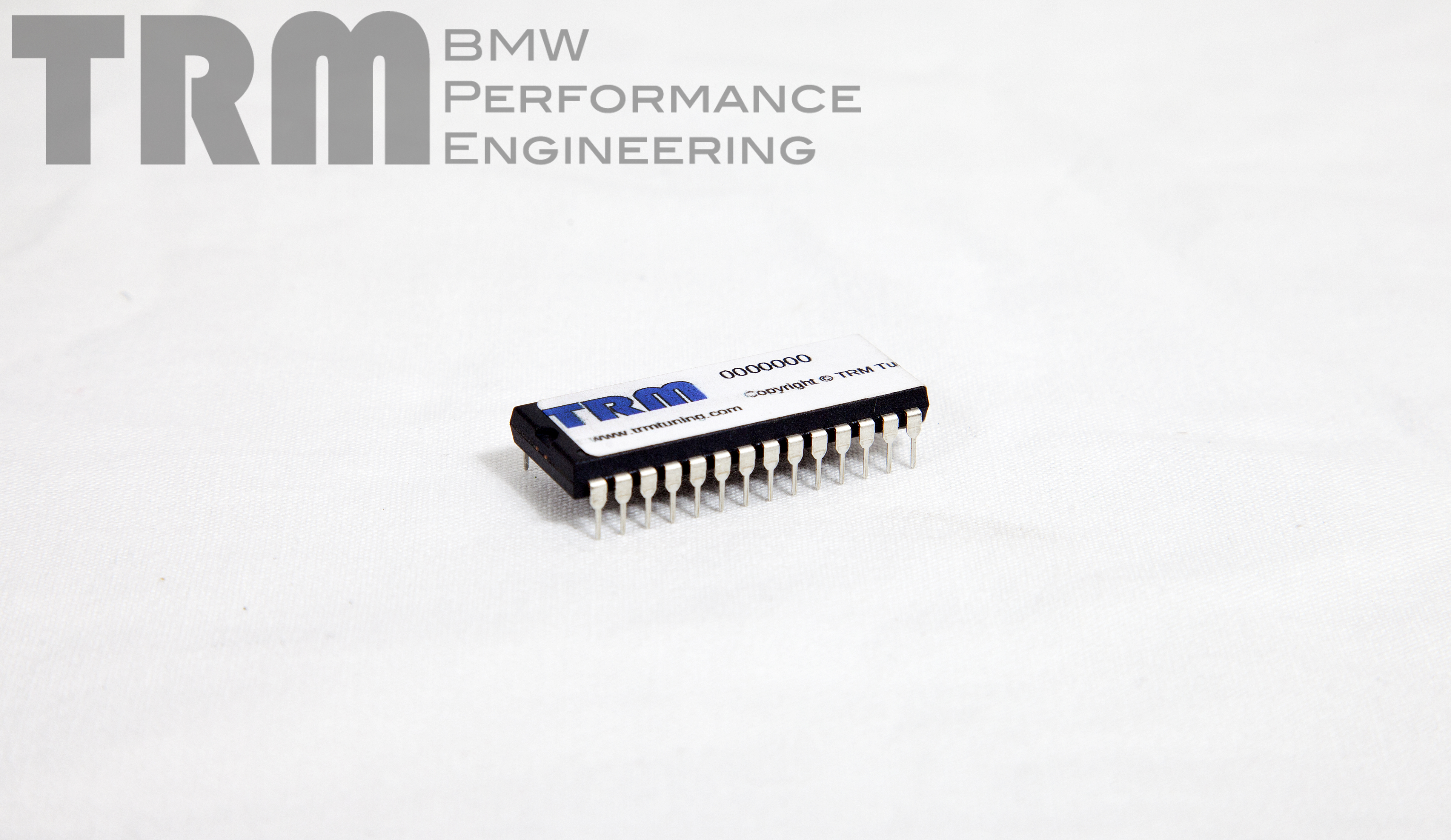

Install the TRM chip. Make sure to align the notch on the end of the chip with the notch on the end of the socket.

Replace the chip lock/cover.

Replace the ECU cover.

Plug ECU into harness.

Slide ECU back into compartment.

Replace the plastic cover making sure to properly seat the harness in the cover before screwing it down.

Replace the sound cover.

You must be logged in to post a comment.